Optimizing development resources for efficient product development

Nowadays, efficient process research and development are, more than ever, an absolute must for contract manufacturers and API manufacturers. New products/processes need to be pushed through to market readiness faster and faster. However, development departments suffer from a shortage of resources and the available employees are often overburdened with administrative tasks. So it is no wonder that in many cases there is no time for serious process development anymore. Time-consuming routine work such as dosing, tempering and similar control tasks can be left to an automated laboratory reactor while limited human resources can then be used for more important work.

Download “Appl. Optimizing…”

Application Note “Optimizing Development Resources…”

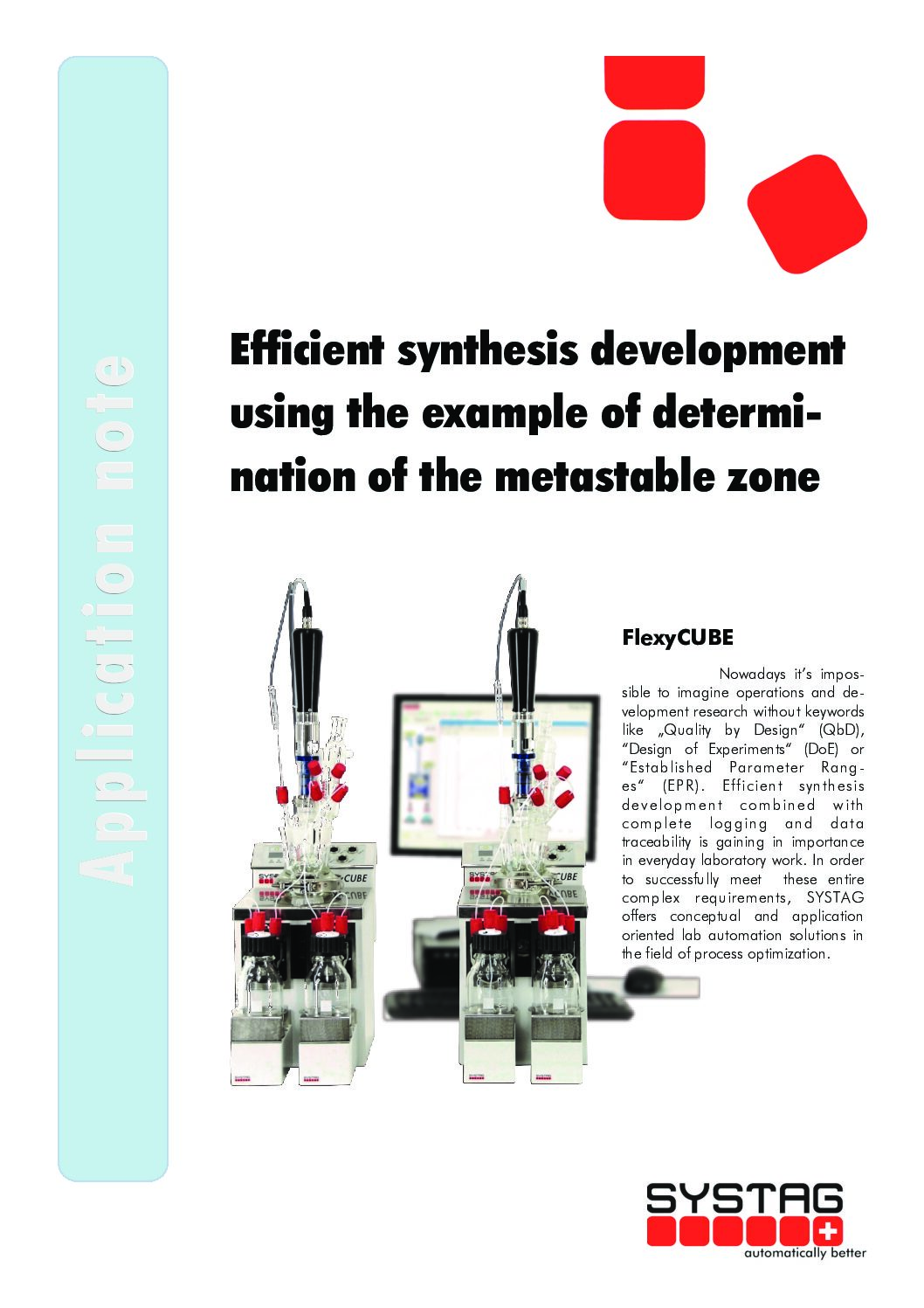

Parallel Synthesis Workstation – Efficient synthesis development using the example of determination of the metastable zone

The objective is a successful efficiency enhancement of laboratory work in the general process of development for R&D purposes, as well as in particular in EPR-Operations (Established Parameter Ranges). Reproducible, individual, independent and complete recorded test series are necessary to determine and interpret the metastable zones of a product solvent mixture.

Download Application

Application Note “Efficient synthesis development using the example of determination of the metastable zone”

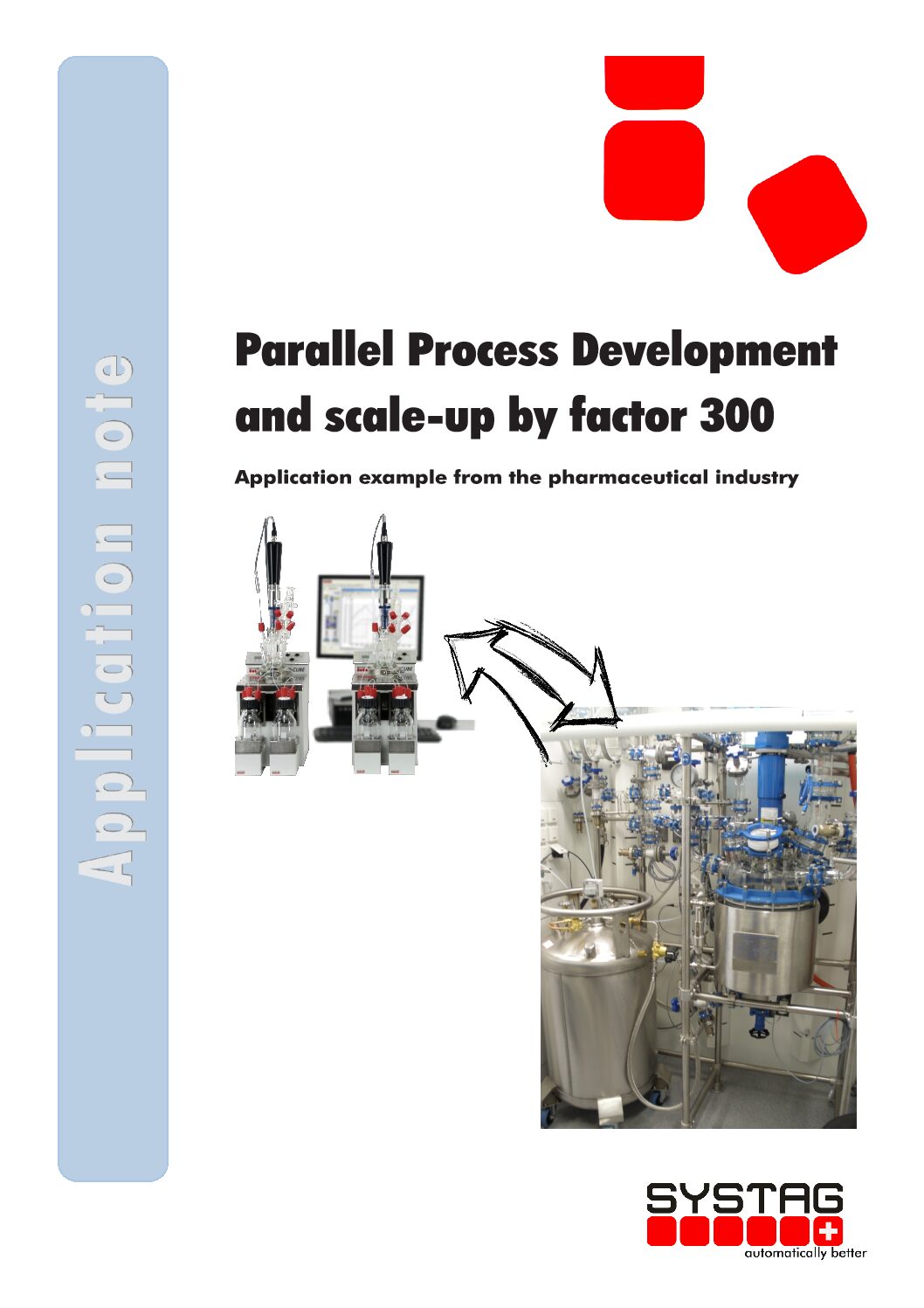

FlexyPlant – Scale-Up application example from the pharmaceutical industry

In the present application from the pharmaceutical process development, the aim is to transfer processes from the 70ml reactor into the 25lt scale, as efficiently and reproducibly as possible. In most cases, such a scale-up step takes place in different laboratories, in fully diversified plants. A great deal of information may be lost, and the knowledge of development Chemists can usually not be implemented optimally.

Download Appl.-Note (Scale-Up R&D)

“Scale-Up Application in R&D”

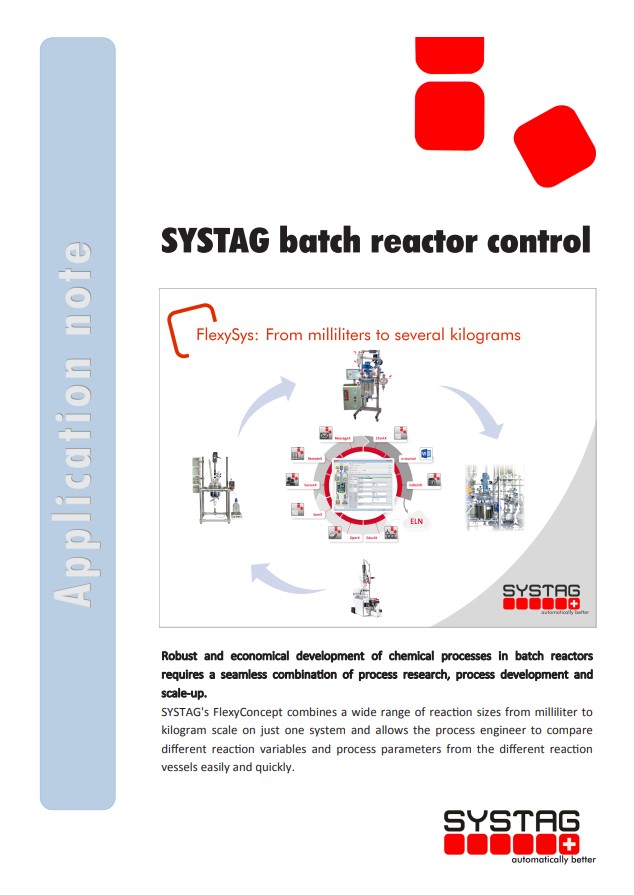

Batch reactor control in R&D and Kilo-Lab

Robust and economical development of chemical processes in batch reactors requires a seamless combination of process research, process development and scale-up.

Download Flyer batch reactor control

Application Note “Batch reactor control”

FlexyPlant – Application example in process development

The requirement was to install a universal scale-up reactor with a working volume of 20 litres in a process technology department. The client required the following additional characteristics:

Download Flyer (FP_01e)

Application Note “Application example in process development”