FlexyPAT – Reactors can be automated individually

Functional – cost-optimised – user-friendly

- Minimum training requirements, high acceptance by personnel and fastest possible efficiency thanks to intuitive operation

- Cost-effective thanks to possible integration of existing devices

- Investment protection through continuous future-oriented development

Flexible automation for synthesis, kilo lab and mini plant

Concept

- Several jacketed reactors can be operated from a single PC

- Customised turn-key systems

- The FlexyPAT concept facilitates the integration of existing customer-owned hardware. Not only does this reduce the cost but it also speeds up the automation process and increases user acceptance.

- Simple and inexpensive system extension possible at all times

- User-friendly system configuration through integrated sensor identification

Standard functions

- Gravimetric or volumetric dosing

- Jacketed reactor: Temperature control of jacket and reactor

- Stirrer control including speed and torque measurements

- pH measurements

- Manual and recipe controls

- Data capture and automatic laboratory report

Flexibility through options

- Automatic distillation with reflux splitter

- Pressure and vacuum measurement and control

- Hydrogenation capabilities

- Isothermal heat flow calorimetry

- Automatic distillation with boiling point detection

- Automatic establishing of solubility curves

- Isothermal heat flow calorimetry

- Possibility to integrate online sensors (turbidity measurement, midIR FTIR, particle size measuring instruments, etc.)

- GLP and CFR21 part 11, IQ/OQ on request

Also compatible with…

- CollectX – Real time data link to your laboratory informatics

- RemoteX – Control your reactors with mobile devices

- InProcess PAT – Particle size analyzer with BlazeMetrics

(Click on the text for further information)

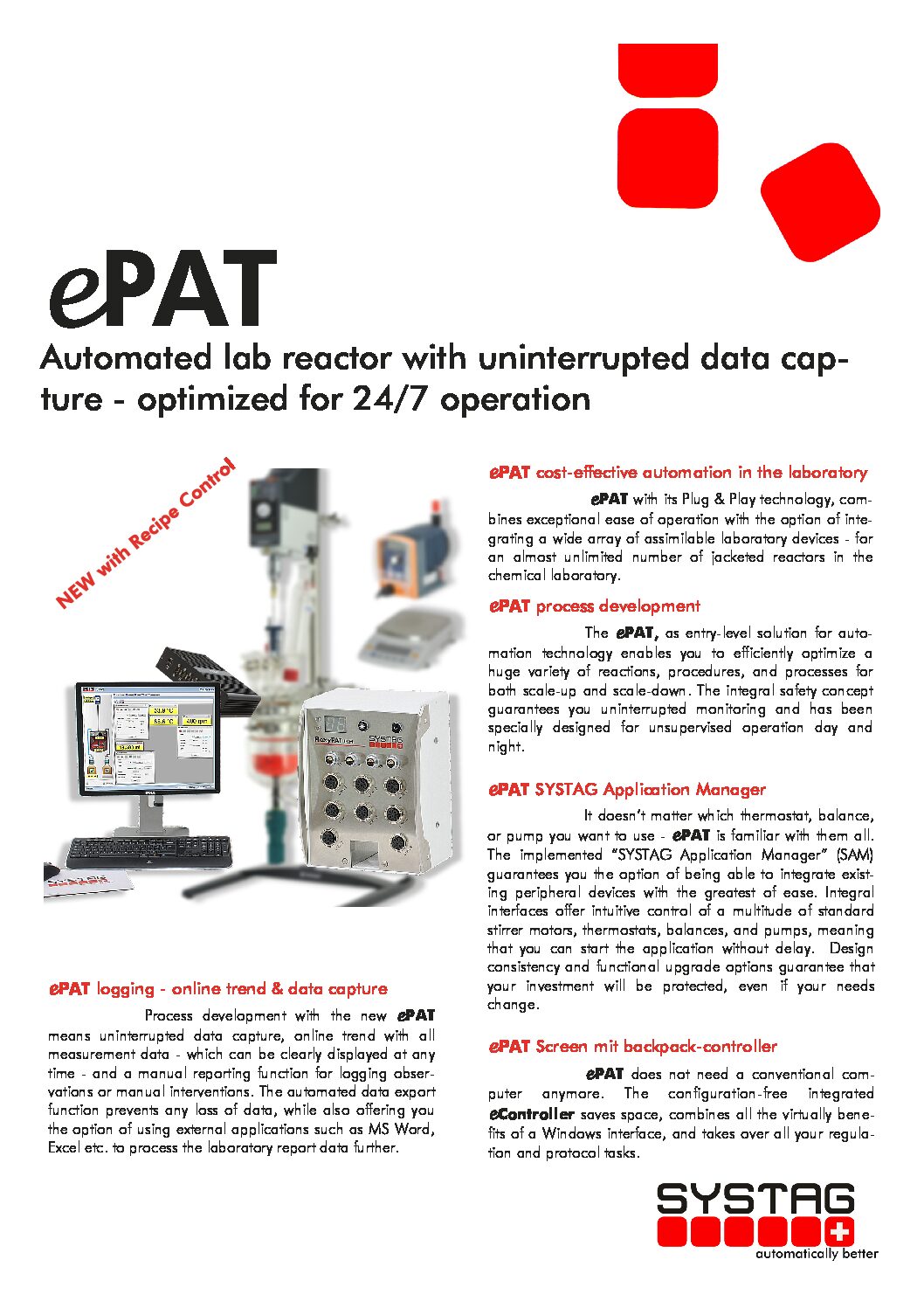

ePAT – for various reactions and processes

Quick, easy, inexpensive

- Optimize your synthesis & processes

- cost-effective entry solution into automation technology

- Logging – online trend & data capture

- Plug & Play technology

- All common laboratory equipment integrable

Automation of jacketed reactors for research and development

The Concept

- ePAT combines with its Plug & Play technology, exceptional ease of operation with the option of integrating a wide array of laboratory devices – for an almost unlimited number of jacketed reactors in the chemical laboratory.

- ePAT, as entry-level solution for automation technology optimizes various reactions and processes.

- ePAT and the integral safety concept guarantees you uninterrupted monitoring, specially designed for unsupervised operation day and night.

- ePAT does not need a conventional computer. The integrated eController takes over all your regulation and protocol tasks.

The Functionality

- Stirring with logging of torque measurement

- Temperature control loop for reactor- and jacket control mode, with control parameter tuning function

- Two dosage control loops with temperature-controlled feed rates

- pH-measurement & control (single-side)

- Pressure measurement

- Recipe editor and recipe control mode

- Safety monitoring, online trending and event logging

- ePAT Plug & Play technology

- Pt-100, RS232, analog input/output, digital signals

- Automatic sensor detection

- Integrated function to calibrate the reactor temperature sensor

Reactors and accessories

ePAT Basic - controlled lab reactor for R&D „Ready-to-Run”

Consisting of:

- ePAT control Unit

- 1000ml jacketed glass reactor DN100, complete

- Stirrer motor Heidolph Hei-TORQUE Precision

- Huber Ministat 230w, -40 … +200°C, PilotONE

- Weight controlled dosage, capacity 5kg, 1.1 lt/h

| Working temperature range: | -20°C … +180°C |

| Pressure range: | 10 … 1300 mbar abs. |

ePAT basic is an automated, jacketed glass reactor with common functionality, dedicated for the chemical or pharmaceutical laboratory to do scale up/scale down process development. Even complex experiments can be worked out with the intuitive and user-friendly application software. The experiment is fully documented and reproducible.

ePAT Jacketed Reactor, compl., 500ml

Consisting of:

- 500ml Jacketed reactor DN100, bottom valve 10mm, TR Pt-100 sensor, condenser, Stirrer bearing mechanical seal, pitched blade impeller stirrer, double cardan coupling

- Reactor lid DN100, central NS45/40, lateral 1x NS14/23, 3x NS29/32

- Heating/cooling connection 2x KS19/9, adapter 19/9 to hose nozzle 12mm

- Reactor mounting (SS316) with V-stand, for reactors up to 5lt

| Temperature Range: | -50°C … +200°C |

| Pressure Range: | 10 … 1300mbar abs. |

| WxHxD: | 500x1300x500mm |

ePAT Jacketed Reactor, compl., 1000ml

Consisting of:

- 1000ml Jacketed reactor DN100, bottom valve 10mm, TR Pt-100 sensor, condenser, Stirrer bearing mechanical seal, pitched blade impeller stirrer, double cardan coupling

- Reactor lid DN100, central NS45/40, lateral 1x NS14/23, 3x NS29/32

- Heating/cooling connection 2x KS19/9, adapter 19/9 to hose nozzle 12mm

- Reactor mounting (SS316) with V-stand, for reactors up to 5lt

| Temperature Range: | -50°C … +200°C |

| Pressure Range: | 10 … 1300mbar abs. |

| WxHxD: | 500x1300x500mm |

ePAT Jacketed Reactor, compl., 5lt

Consisting of:

- 5lt Jacketed reactor DN100, bottom valve 10mm, TR Pt-100 sensor, condenser, Stirrer bearing mechanical seal, pitched blade impeller stirrer, double cardan coupling

- Reactor lid DN100, central NS45/40, lateral 1x NS14/23, 3x NS29/32

- Heating/cooling connection 2x KS19/9, adapter 19/9 to hose nozzle 12mm

- Reactor mounting (SS316) with V-stand, for reactors up to 5lt

| Temperature Range: | -50°C … +200°C |

| Pressure Range: | 10 … 1300mbar abs. |

| WxHxD: | 500x1300x500mm |

Stirrer motors and accessories

ePAT Stirrer motor Heidolph Hei-TORQUE Precision 100

Technical specification:

- 10-2000 rpm, max. torque 100 Ncm, incl. torque measurement

- incl. RS232 cable, 5 m

- excl. cardan coupling

ePAT Stirrer motor IKA Eurostar Control 60

Technical specification:

- 30-2000 rpm, max. torque 60 Ncm, incl. torque measurement

- incl. RS232 cable, 5 m

- excl. cardan coupling

Thermostats and accessories

ePAT include in the basic system communication drivers for the most common thermostats. Detailed information is available in the ePAT compatibility file. Furthermore, as an option, electrical heated control systems can be integrated as well. Of course, existing peripheral equipment can be used.

Controllable models:

- Huber Unistat / CC / PilotOne / KISS / OLE / …

- Julabo

- Lauda XT-Serie / Proline

Further options:

- heated oil bath with round bottom flasks

- Electric heated reactors

ePAT Huber Ministat 230 w, -40...+200 °C, PilotONE

Technical specification:

- Cooling capacity: 0.42 kW @100 °C, 0.38 kW @0 °C, 0.25 kW @-20 °C

- Heating capacity: 2 kW

- w/o hoses and thermal fluid

ePAT Julabo CF40, -30 … +150 °C

Technical specification:

- Cooling capacity: 0.47 kW @+20 °C, 0.4 kW @0 °C, 0.28 kW @-20 °C

- Heating capacity: 2 kW

- w/o hoses and thermal fluid

Dosage and pH-control

ePAT weight-controlled dosage, 6.2 kg, 1.1 L/h

Consisting of:

- Diaphragm pump Prominent with PFTE pump head, pressure retention

- valve, adapter and Bola-screws

- Balance Precisa up to 6.2 kg, 0.1 g resolution

- 1L bottle with PFTE-dosage adapter, complete

- incl. required cables and mounting platform

ePAT volume-controlled dosage, Metrohm Dosino

Consisting of:

- Metrohm Dosino with 20 mL dosing unit, dosage interface, transfer tube

- incl. USB driver and cable

Extension by Metrohm Dosino 800

- Metrohm Dosino incl. 20 mL dosing unit (as extension for existing Metrohm interface)

ePAT pH-measurement and control (single side)

FlexyPAT pH sensor and pH-amplifier

- incl. glass adapter GL14/NS29 and GL screw joint

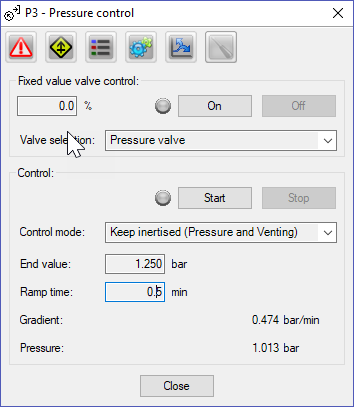

Pressure measurement and control

ePAT Pressure-sensor stainless steel 0…1,6 bar

- incl. cable and GL14-join

ePAT Press-Vent-Vac, set with 3 solenoid valves PTFE, 0...1,6 bar

- Valve set with 3 solenoid valves, PTFE/PFA, up to 1,6 bar abs.

- Installed on a platform to fix at the rack

ePAT Press-Vent-Vac control, Software function

-

Control mode:

- Keep inertised (Pressure and Venting)

- Pressure control

- Vacuum control

Individual control for each valve:

- Pressure valve

- Venting valve

- Vacuum valve

Safety:

- Emergency limit with safe state activation

- Set.value-act.value monitoring

- Interlock of valve function

Requires „Press-Vent-Vac, set with 3 solenoid valves PTFE“ set

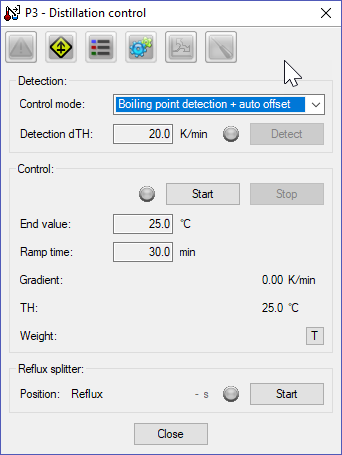

Distillation control

ePAT Automatic distillation, Software function

Key Features:

- Autom. Boiling Point detection by TH

- Autom. Temp. Set point control by off-set definition

- various, definable abort criteria such as temperature rise or distillate quantity

- Control of the return flow via DOT (requires autom. Reflux divider)

ePAT Distillation hardware with reflux splitter V2

- complete glassware with solenoid reflux splitter and PT100 for temperature head

- suitable for Joint NS29/32

- incl. condenser and receiver